Discover the Vibrating Sieve Machine: Tips, Insights, and Applications

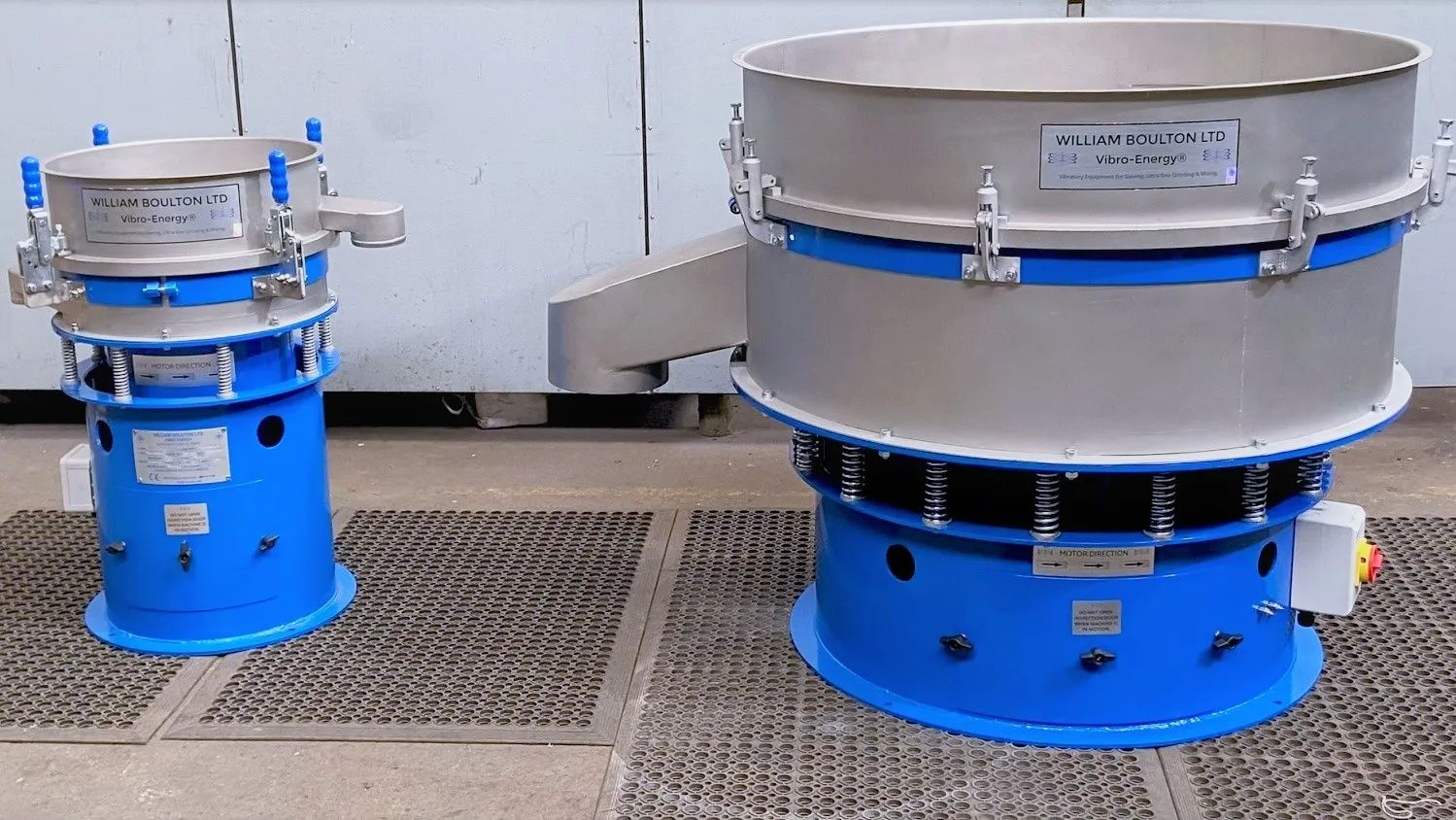

A vibrating sieve machine, also known as a vibrating screen or separator, is a mechanical device used to separate materials based on particle size. It works by using vibration to move materials across a screen mesh, allowing smaller particles to pass through while larger particles remain on top. These machines are widely used in industries like food processing, pharmaceuticals, chemicals, mining, and recycling.

They exist to improve efficiency, ensure product quality, and meet industry standards where precise particle separation is required. From sorting flour in bakeries to classifying minerals in mining operations, vibrating sieve machines play a crucial role in production processes.

Why vibrating sieve machines matter today

In today’s industrial environment, precision, speed, and hygiene standards are increasingly strict. Vibrating sieve machines help businesses and laboratories meet these demands by:

-

Ensuring product consistency – Helps maintain uniform particle size.

-

Improving quality control – Removes unwanted materials or contaminants.

-

Reducing waste – Separates usable product from scrap material.

-

Boosting efficiency – Processes large quantities quickly and with minimal manual intervention.

Who benefits:

-

Food and beverage manufacturers (e.g., flour, sugar, spices)

-

Pharmaceutical companies (powder screening)

-

Chemical producers (granules and powders)

-

Mining and construction firms (aggregates and minerals)

-

Recycling plants (plastic and metal sorting)

Without reliable sieving, products risk contamination, uneven texture, and reduced shelf life, potentially impacting safety and compliance.

Recent updates and trends (2024–2025)

The vibrating sieve machine industry has seen several notable developments in the past year:

| Trend | Details |

|---|---|

| Automation integration | Many new models now feature automated feed and discharge systems, reducing manual labor. |

| Hygienic design improvements | In food and pharma sectors, stainless steel and easy-clean designs have become standard. |

| Energy efficiency | Manufacturers are introducing energy-saving motors and smart vibration controls. |

| Noise reduction technology | Quieter operation for better workplace safety and comfort. |

| IoT connectivity | Sensors monitor machine performance, predict maintenance needs, and send alerts. |

In February 2025, several manufacturers at the International Processing & Packaging Expo showcased AI-enhanced sieving machines capable of real-time product quality analysis.

Laws, standards, and policies affecting vibrating sieve machines

Regulations for vibrating sieve machines vary by industry and region but generally focus on safety, hygiene, and environmental compliance.

| Regulation / Standard | Region | Key Requirements |

|---|---|---|

| FDA Food Contact Regulations | USA | Requires food-contact sieves to use approved materials. |

| GMP (Good Manufacturing Practices) | Global | Ensures equipment is designed for hygiene and quality. |

| OSHA Machinery Standards | USA | Safety guards, noise limits, and operator training. |

| CE Marking | EU | Confirms compliance with European health and safety standards. |

| ISO 9001 & ISO 22000 | Global | Quality management and food safety certification standards. |

Businesses must ensure machines meet relevant safety certifications and industry requirements to avoid penalties and ensure product safety.

Tools, resources, and useful references

Machine Selection Tools:

-

Online capacity calculators for screen size and throughput

-

Manufacturer configuration tools (e.g., Russell Finex, Vibroflow)

Maintenance and Operation Resources:

-

OEM manuals and video guides

-

Predictive maintenance software linked to IoT-enabled machines

Industry References:

-

American Society of Mechanical Engineers (ASME) equipment standards

-

Food Processing Suppliers Association (FPSA) technical resources

Training Resources:

-

Online courses on screening efficiency and machine operation

-

Industry webinars on hygiene and safety compliance

Frequently Asked Questions

1. What is the difference between a vibrating sieve and a rotary sifter?

A vibrating sieve uses vibration to separate particles, while a rotary sifter uses a rotating drum or mesh cylinder. Vibrating sieves are faster and more precise for fine materials.

2. How often should a vibrating sieve machine be cleaned?

In food and pharmaceutical industries, cleaning should be done after every batch or shift. In other industries, cleaning frequency depends on the material handled and operational requirements.

3. Can vibrating sieve machines handle wet materials?

Yes, certain models are designed for wet screening, often used in wastewater treatment, food processing, and mining applications.

4. What factors affect screening efficiency?

Mesh size, vibration frequency, feed rate, moisture content, and material characteristics all influence efficiency.

5. Are vibrating sieve machines energy-intensive?

Modern designs are increasingly energy-efficient, with variable speed motors and optimized vibration patterns to reduce power consumption.

Summary comparison of sieve types

| Type | Application | Advantages | Limitations |

|---|---|---|---|

| Circular Vibrating Sieve | Food, pharma, chemicals | High precision, easy to clean | Lower capacity than linear types |

| Linear Vibrating Screen | Mining, aggregates | High capacity, robust | Less precise for fine powders |

| Ultrasonic Sieve | Fine powders, specialty chemicals | Prevents mesh clogging | Higher cost |

Final thoughts

Vibrating sieve machines may seem like simple tools, but their role in ensuring quality, safety, and efficiency in countless industries is critical. With new advancements in automation, hygiene, and performance monitoring, these machines are becoming smarter and more reliable.

Understanding their operation, legal requirements, and maintenance needs can help businesses choose the right equipment and maintain consistent production quality.